What is Varnish?

Varnish is a transparent, hard, protective finish or film primarily used in wood finishing and other materials. Clear varnish is traditionally a combination of drying oil, a resin, and a thinner or solvent. Varnish finishes are usually glossy , but some may produce satin or semi-gloss sheens by adding “flatting” agents. Varnish has little or no color, is transparent, and has no added pigment, as opposed to paints or wood stains, which contain pigment and generally range from opaque to translucent. Varnishes will also cover wood stains as a final step to achieve a film for gloss and protection. Some products combine stain and varnish.

Curing and Evaporation

After applying the film-forming substances in varnishes, either harden directly or set up nicely after evaporating the solvent through the curing processes. Resin varnishes “dry” by evaporation of the solvent and hardens almost immediately upon drying. Acrylic and waterborne varnishes “dry” upon water evaporation but will experience an extended curing period. Oil, polyurethane, and epoxy varnishes remain liquid even after evaporation of the solvent but quickly begin to cure, undergoing successive stages from liquid or syrupy to tacky or sticky to dry gummy, to “dry to the touch,” too hard. Environmental factors such as heat and humidity affect varnishes’ drying and curing times.

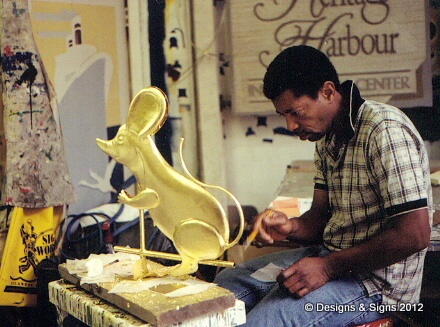

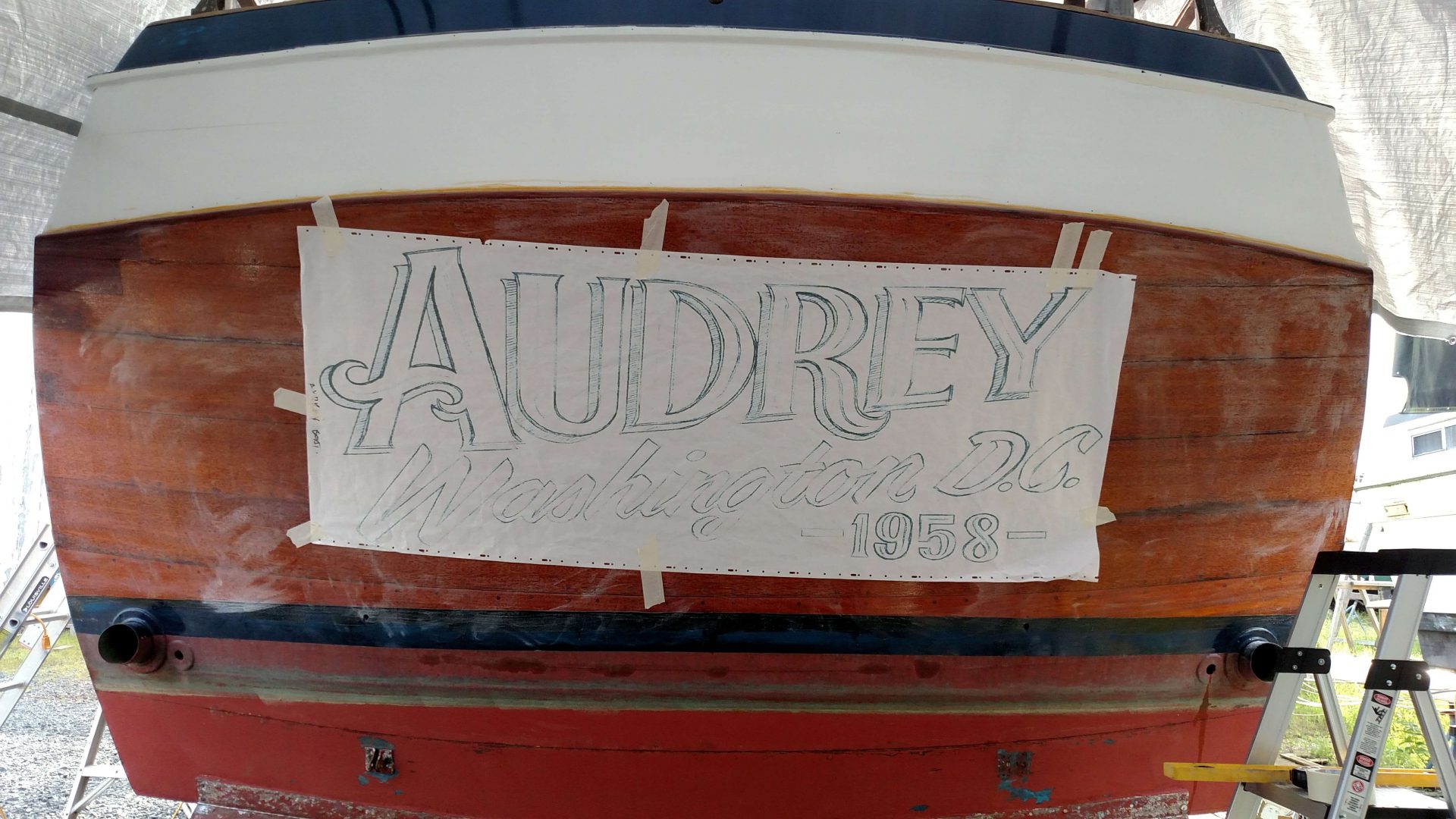

What is the use of varnish?

In short, varnish covers wooden surfaces, paintings, and various decorative objects with protective coatings. This treatment provides protection, and it enhances the appearance of wooden floors, interior wood paneling and trim, furniture, and — of course — wooden signs.

How do you apply Awlgrip Awlspar OM3131 varnish to a surface?

1. Surface Preparation

The wood should be clean, dry, smooth, and well seasoned. For best results, use natural bristle brushes suitable for solvent-based products. For roller application, use either foam or conventional short mohair type (Redtree Deluxe Mohair R-11PH), solvent resistant. New Wood: Using a marine teak cleaner or wood bleach is advised on new wood to remove excess oils and promote color uniformity and adhesion. Follow manufacturer’s instructions for use and thoroughly remove all cleaner and neutralizer residue before proceeding. Rough sawn lumber must receive heavy sanding from leveling the grain. Work through the grits to effectively smooth out the surface.

2. Mixing & Reduction

New Wood Reduction: When finishing new wood, reduce 100% (1 part M3131 to 1 part T0016 by volume) with T0016 for the first coat only. Awlspar will penetrate and seal the grain. For spray application, reduce between 50-100% with T0180.

We should apply subsequent coats with a 25% reduction (T0180). Brush application: thinning or reducers are not typically required (after the first coat). If desired, reduce up to 20% with T0016. Stir only. Do not shake!

3. Application Instructions

First of all, anyone can use Awlspar Classic Spar Varnish to seal the wood and build up a complete finishing system. Alternatively, Awlbrite Quik-Fi Clear J3901/J3902 is a clear, fast-drying wood grain filler that we can use to seal the wood before finishing with Awlspar M3131 (4-6 coats). Apply light, smooth, even coats (2-3 mils wet) of full-bodied material. At temperatures above 77°F, we can apply 2 to 3 coats per day. If sanding is required, allow curing 24 hours before sanding. Best results materialize when the surface is sanded smooth with 320 -400 grit paper after every 2 to 3 coats. Your boards may need 7-10 coats. Finally, The exact number of coats required will vary by applied film thickness, the amount of sanding, and the type of wood.

More information from the manufacturer at Awgrip.com