We are Sandblasting Stone Letters experts!

First, members of Brantwood Overlook HOA contacted us about this problem they have with their neighborhood entrance sign. They have a beautiful stone wall, and pillars with an inset polished black granite sign face. However, for some reason, builders never finished their sign. Instead, the original builders applied vinyl lettering to the polished granite face. After a few years, the vinyl lettering began to fail, and the residents at Brantwood Overlook started looking for a permanent solution.

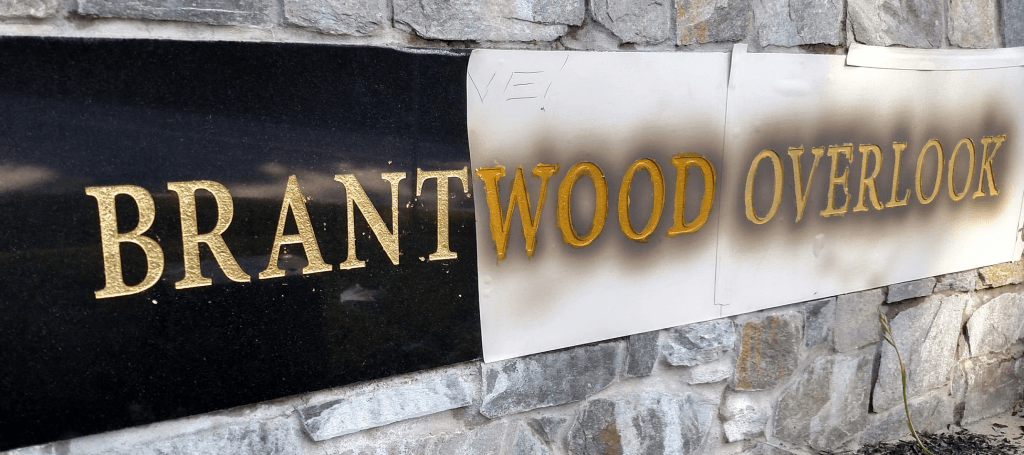

Vinyl lettering on polished granite, not good!

A beautifully polished granite sign face with failing vinyl letters. We can fix this sign with permanent sandblasted letters and a 23 karat gold leaf!

We visited Brantwood Overlook to take a look at their sign. Within a few days, we provided a quote, and then the HOA agreed to hire us for the job. The next part of the process is choosing a font. For this purpose, Travis Brandon compiled an extensive font portfolio. He purposefully presented a selection of appropriate fonts for sandblasting stone letters. We can not remove sandblasted letters, so once we begin work, there’s no going back! Choosing the right font is essential, as there are no do-overs when we blast a sign face.

We blast letters through a rubber mask.

First, we position a rubber mask over the wall with strong adhesive. The adhesive is powerful enough, even for some rough and uneven surfaces. When blasting begins, the sand carves away at the exposed area, the letters. The compressor pushes the sand against the polished stone. Slowly the letters begin to form into the granite, while the shiny background remains protected. And glossy because of the rubber masking. Kevin uses a sandblasting mask. Fresh air is pumped into the mask to protect him from particles in the air. Without the proper protection, the sandblasting process is dangerous and could damage our lungs quickly.

Sizing is the next important step.

We have provided this detailed photo of the sizing process. We leave the masking on as this prevents the size from sticking to the face of the polished granite. The gold leaf will stick to every part of the sign where size is, so that is why we need to be careful with the size. Hence, leaving the rubber mask in place is necessary until all of the size is in the letters. Finally, we are ready to gild and we do not have to worry about making a mess with the gold leaf on the polished face.

Tap the gold leaf gently with a soft brush.

A detailed photo of gold leaf applied to the sandblasted letter. Tamping with a soft bristle brush is used to push the gold leaf onto the size gently. It’s vital to lay the gold at the right time. Too soon, and the gold leaf will not stick to the wet size. Likewise, if we wait too long, the dry size will also reject the gold leaf.

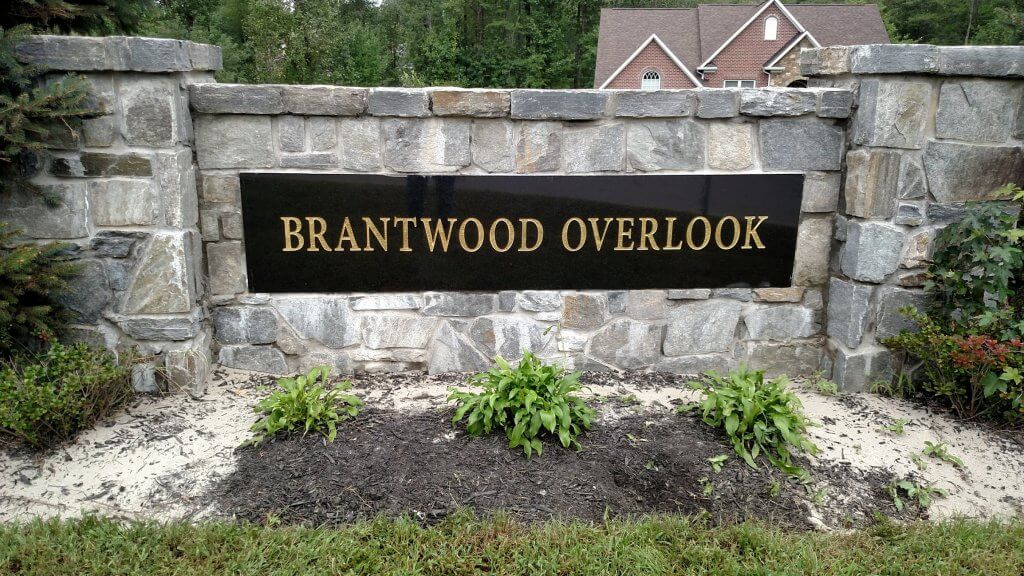

We finish stone letters with 23 Karat Gold Leaf!

Indeed, we enjoy working for the HOA at Brantwood Overlook. Now their amazing polished granite sign looks SO MUCH BETTER! Also, this sign will last forever because sandblasting stone letters are permanent. Granite lasts forever, so it follows that your carved letters will also stand the test of time. Naturally, whenever we make signs in granite, they are well suited for outdoor use. Occasionally we will have to refinish the gold leaf. Occasional gold leaf restoration is ypical for any carved stone lettering.